Description

- Features:

1. Emitted Color: UVC

2. Lens Appearance: Clean quartz lens

3. 3.5×3.5×1.6mm standard package.

4. Suitable for all SMT assembly methods.

5. Compatible with infrared and vapor phase reflow solder process.

6. Compatible with automatic placement equipment.

7. This product doesn’t contain restriction

Substance, comply ROHS standard.

- Applications:

1. Sterilize

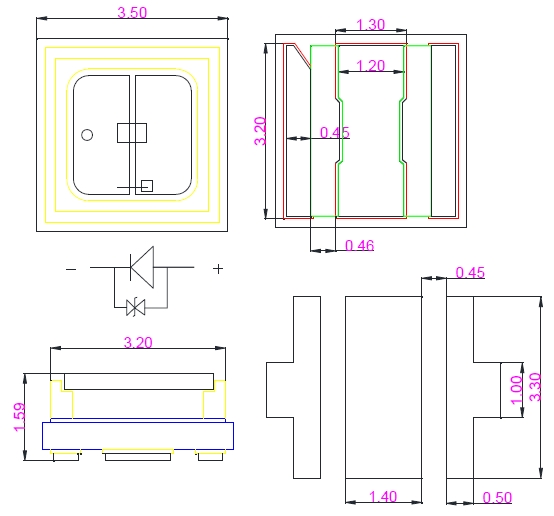

- Package Dimensions:

NOTES:

NOTES:

1. All dimensions are in millimeters.

2. Tolerance is ±0.10mm unless otherwise specified.

3. Specifications are subject to change without notice.

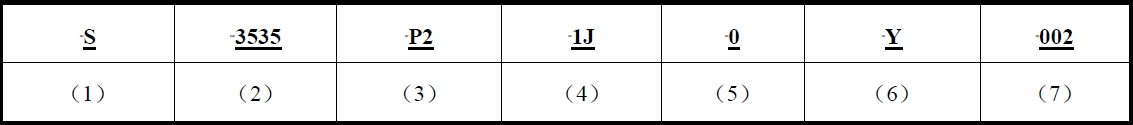

- Part Numbering System:

(1)B: Substrate code

(2)Package type: 3535

(3)LED Color:P2 means UVC segment

(4)Chip code

(5)0:CRI not required

(6)Y:Type of adhesives

(7)002: Specification difference code

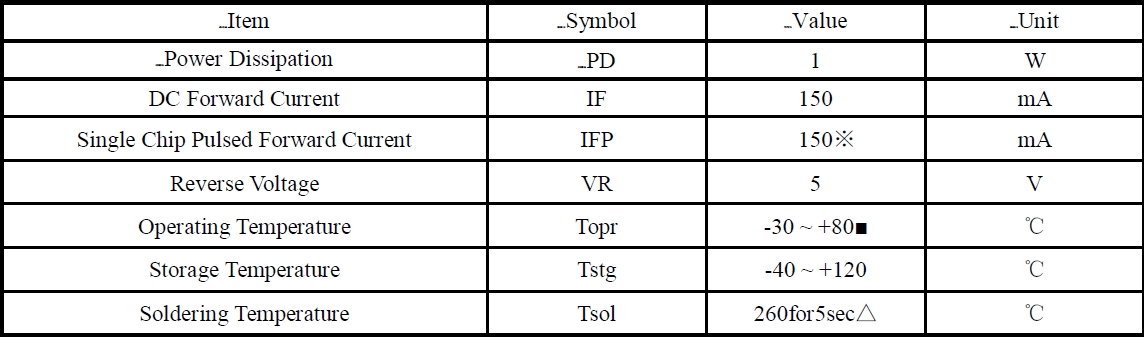

- Absolute Maximum Ratings(Ta=25℃)

※Duty 1/10, Pulse Width 0.1ms.

Soldering △ time max 10sec

■please refer to IF-Ta diagram of curves for the temperature during application

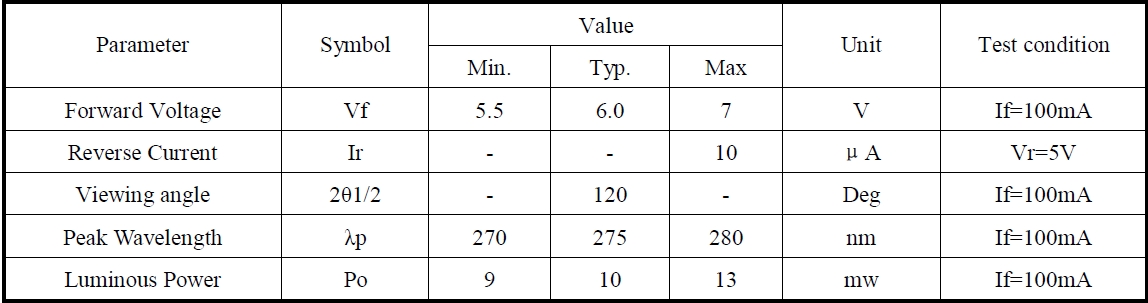

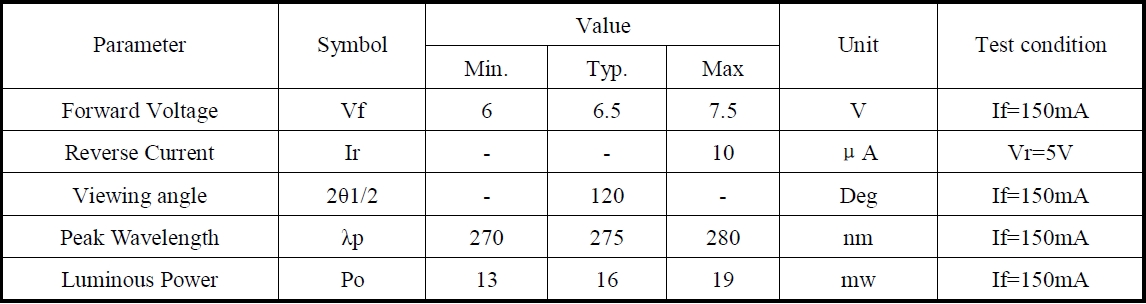

- UVC parameter

100mA

150mA

- Soldering :

1. Manual Soldering

The temperature of the iron tip should not be higher than 350℃and Soldering time to be within 3 seconds per

solder-pad.

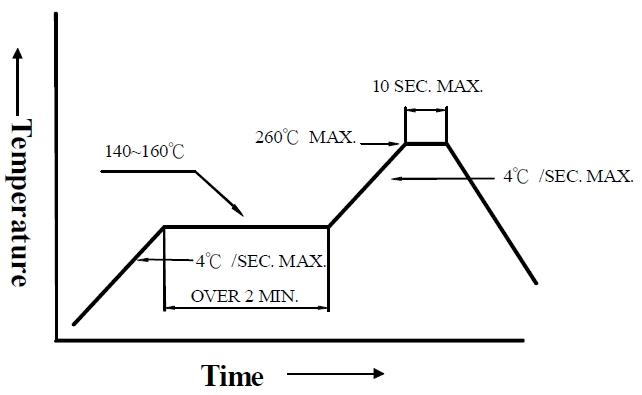

2. Reflow Soldering

Preheating : 140℃~160℃±5℃,within 2 minutes.

Operation heating : 260℃(Max.) within 10 seconds.(Max)

Gradual Cooling (Avoid quenching).

- Storage:

In order to avoid the absorption of moisture, it is recommended to solder BINGRI LEDs as soon as possible after

unpacking the sealed envelope.

If the envelope is still packed, to store it in the environment as following:

(1) Temperature : 5℃-30℃(41℉)Humidity : RH 60﹪Max.

(2) After this bag is opened, devices that will be applied to infrared reflow, vapor-phase reflow, or equivalent

soldering process must be:

a. Completed within 168 hours.

b. Stored at less than 30% RH.

(3) Devices require baking before mounting, if:

(2) a or (2) b is not met.

(4) If baking is required, devices must be baked under below conditions:

48 hours at 60℃±3℃.